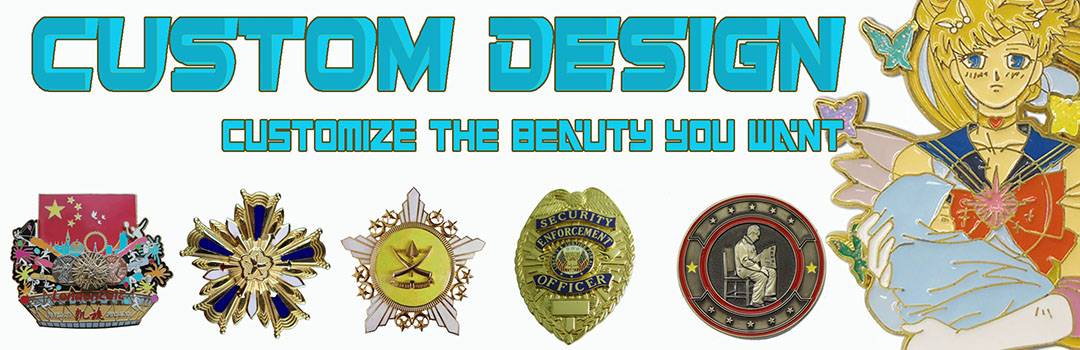

OEM/ODM Factory Pin Badge Custom Lapel - Hard enamel – Kingtai

OEM/ODM Factory Pin Badge Custom Lapel - Hard enamel – Kingtai Detail:

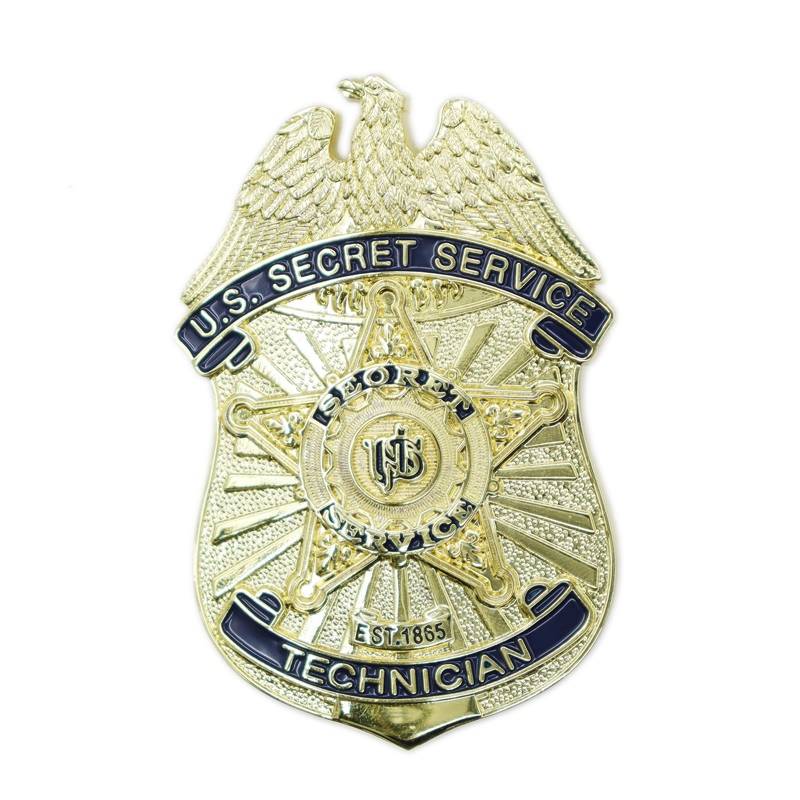

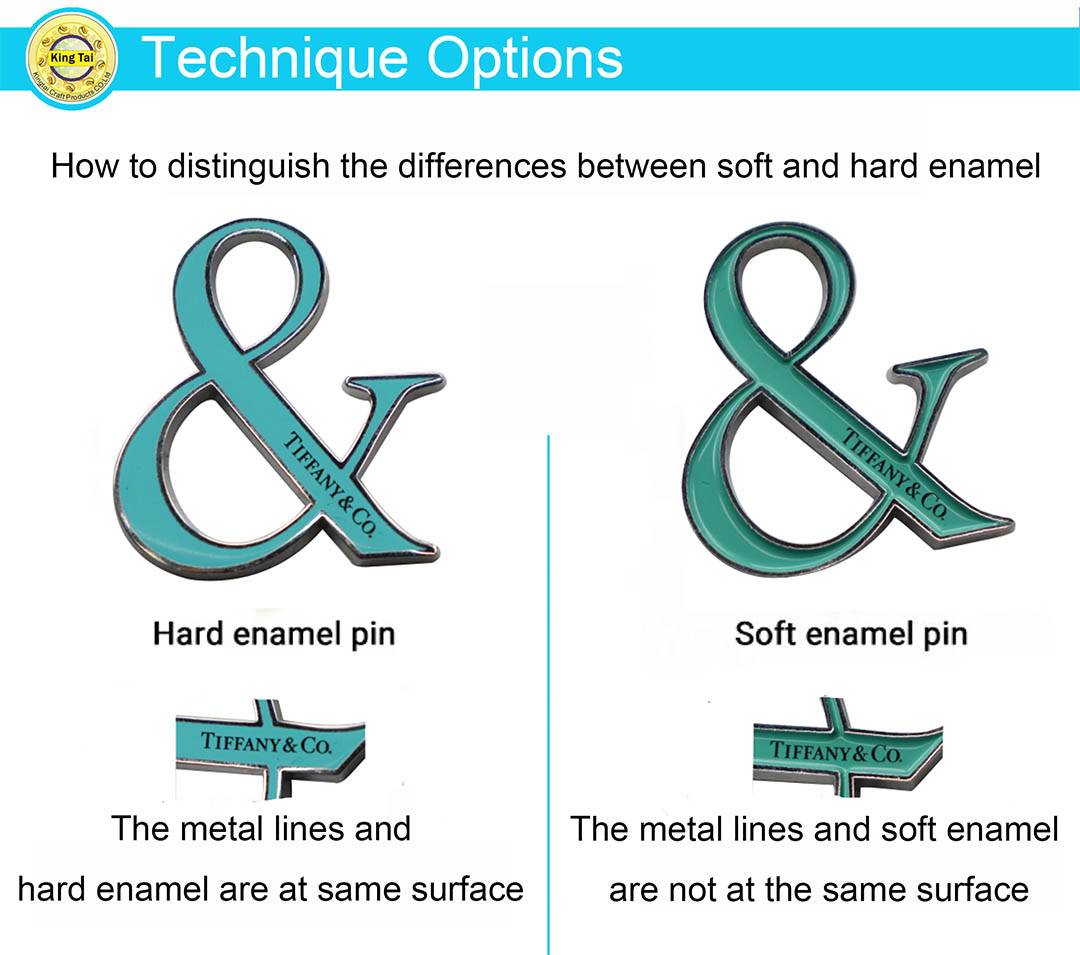

If you’ve ever studied making your own enamel pins, you’ve probably come across the terms “hard enamel” and “soft enamel.”I think a lot of people have the same question: What’s the difference between the two?The biggest difference between hard enamel and soft enamel is the texture of the finished product.Hard enamel pins are smooth and smooth, with good color reflection. The surface is wireless, and the metal edge of soft enamel pins is convex.Both methods use the same metal mold, and both have bright and vibrant colors.But there are some special choices that are specific to soft enamel.

When to Pick Hard Enamel Hard enamel pins are more durable and scratch-resistant compared to soft enamel. Many people choose hard enamel over soft enamel because of the clean, finished look. Many designs can work in both hard and soft enamel, so most of the time it comes down to personal preference. Hard enamel pins are first filled in with color, then the pin’s face is ground down to be flat and smooth. The grinding and polishing makes them incompatible with certain metal finishes. If you want a standard gold or silver metal plating, then hard enamel might be a good choice for your design.

Hard enamel pins are more durable and scratch resistant than soft enamel pins.

Many people choose hard enamel over soft enamel because of its clean and bright appearance.

Many designs are available on both hard and soft enamel, so most of the time it depends on personal preference.

The hard enamel pin is first colored and the surface of the pin is smoothed.

Grinding and polishing make them incompatible with certain metal surfaces.

If you want a standard gold or silver metal plating, hard enamel is a good choice for your design.

Hard Enamel

For hard enamel, the enamel is added before the plating is added, the enamel is added and polished flat to the same level as the metal die lines. Each colour must be baked in the oven one by one which adds to the process and cost. Once all the colours have been added then the badge can be electroplated and polished again to complete the badge. The numerous polishing process is why the badge can achieve slightly less detail than soft enamel and why some of the metal lines are likely to spread in production and be thicker than the original design. Our hard enamel process is a modern process of the traditional hard enamel process and the main difference between our hard enamels is the actual enamel.

For hard enamel, add enamel before electroplating and then polish to the same plane as the metal line.Each color must be baked one by one in the oven, in pursuit of higher quality but increased production process and cost.Once all the colours have been added, then the badge can be plated and polished again to complete the badge.It took a lot of polishing to enable the badge to achieve slightly less detail than soft enamel, and why some of the wire may be diffused in production and thicker than the original design.Our hard enamel process is a modern process, the main difference between the traditional hard enamel process and our hard enamel is the actual enamel.

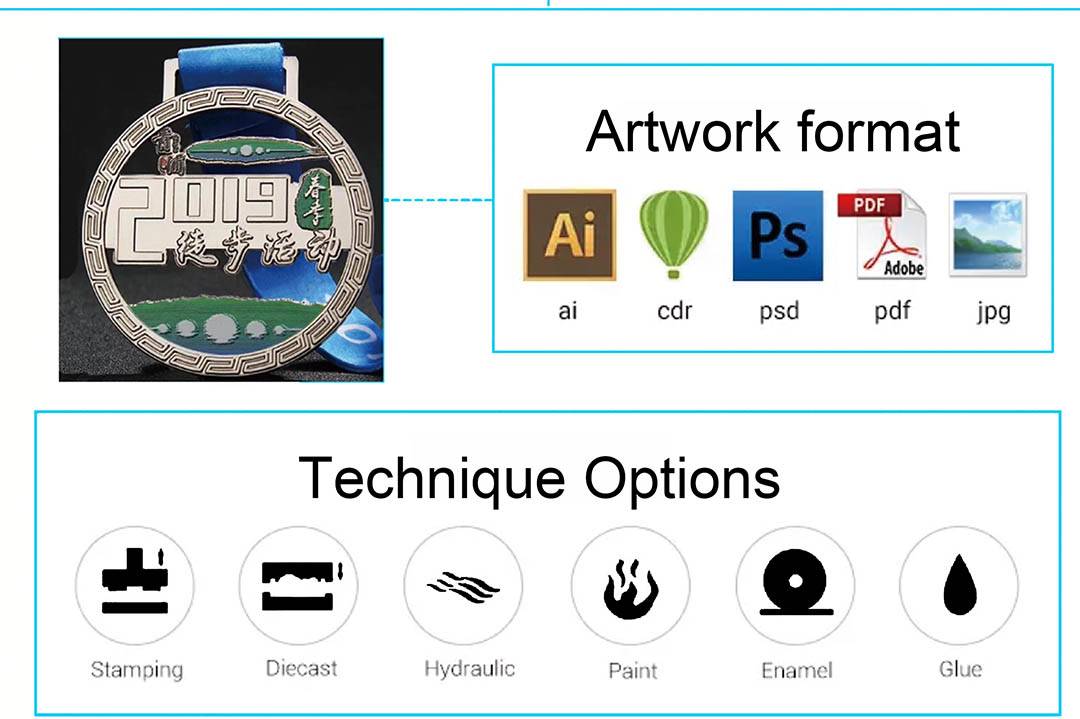

Product detail pictures:

Related Product Guide:

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for OEM/ODM Factory Pin Badge Custom Lapel - Hard enamel – Kingtai , The product will supply to all over the world, such as: Italy, Greek, United States, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!